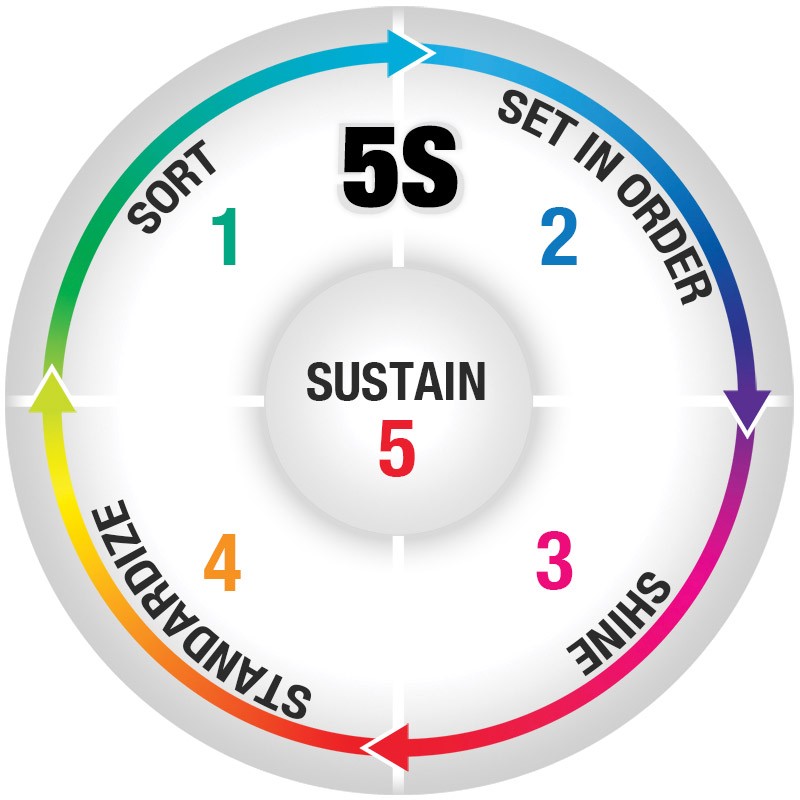

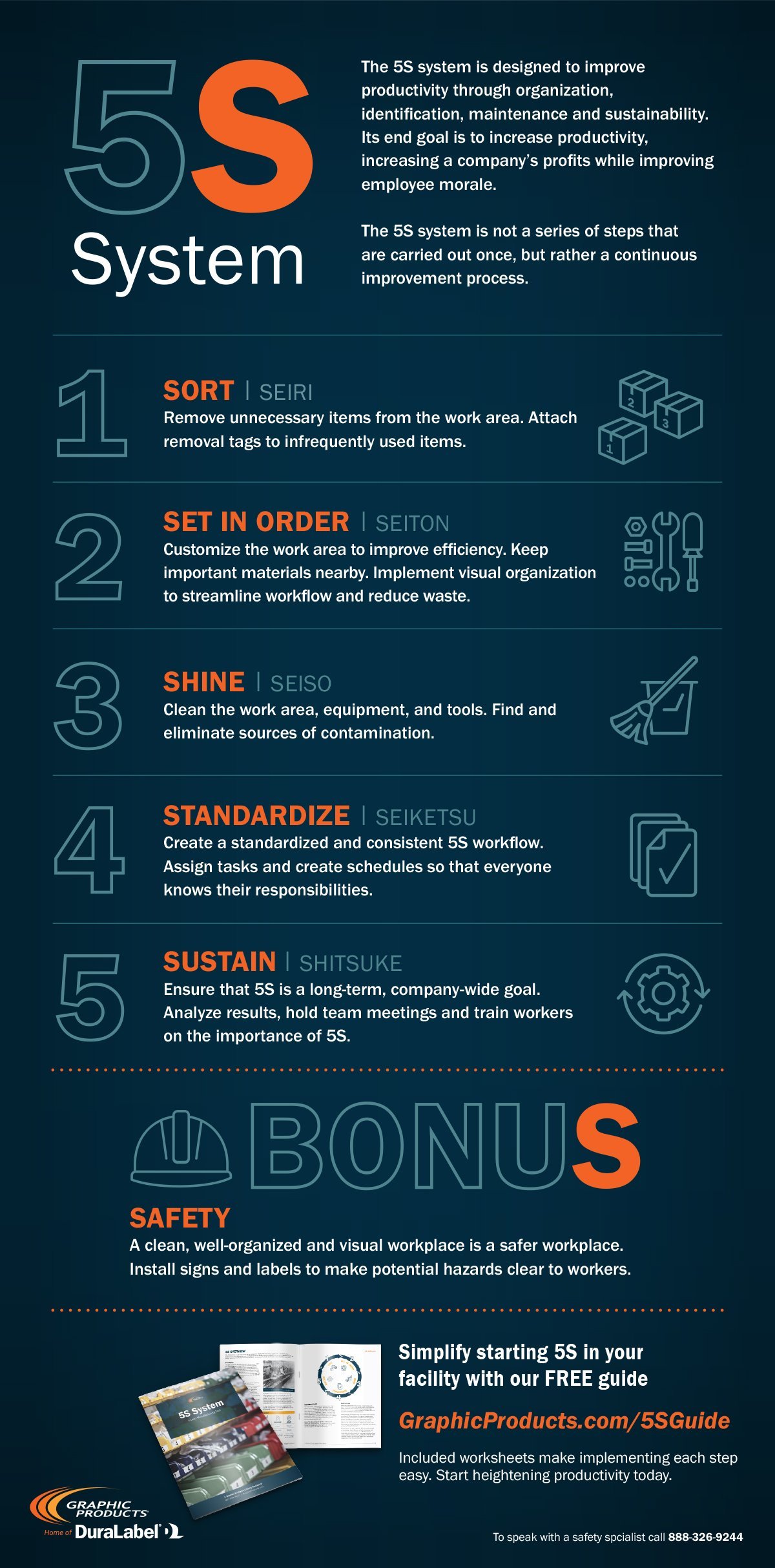

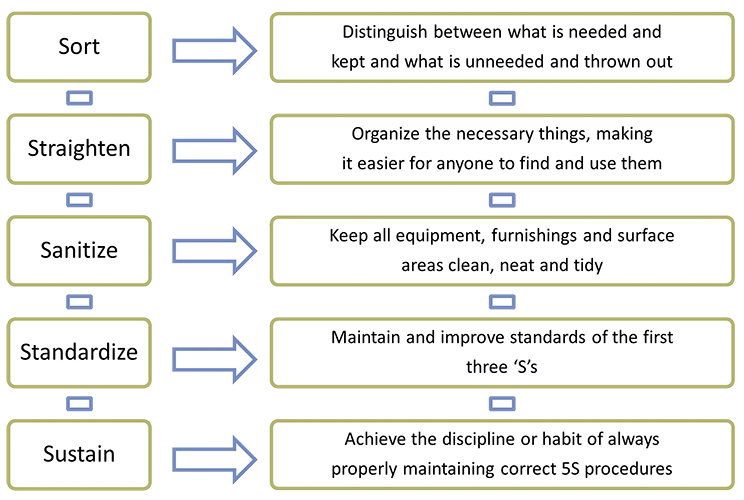

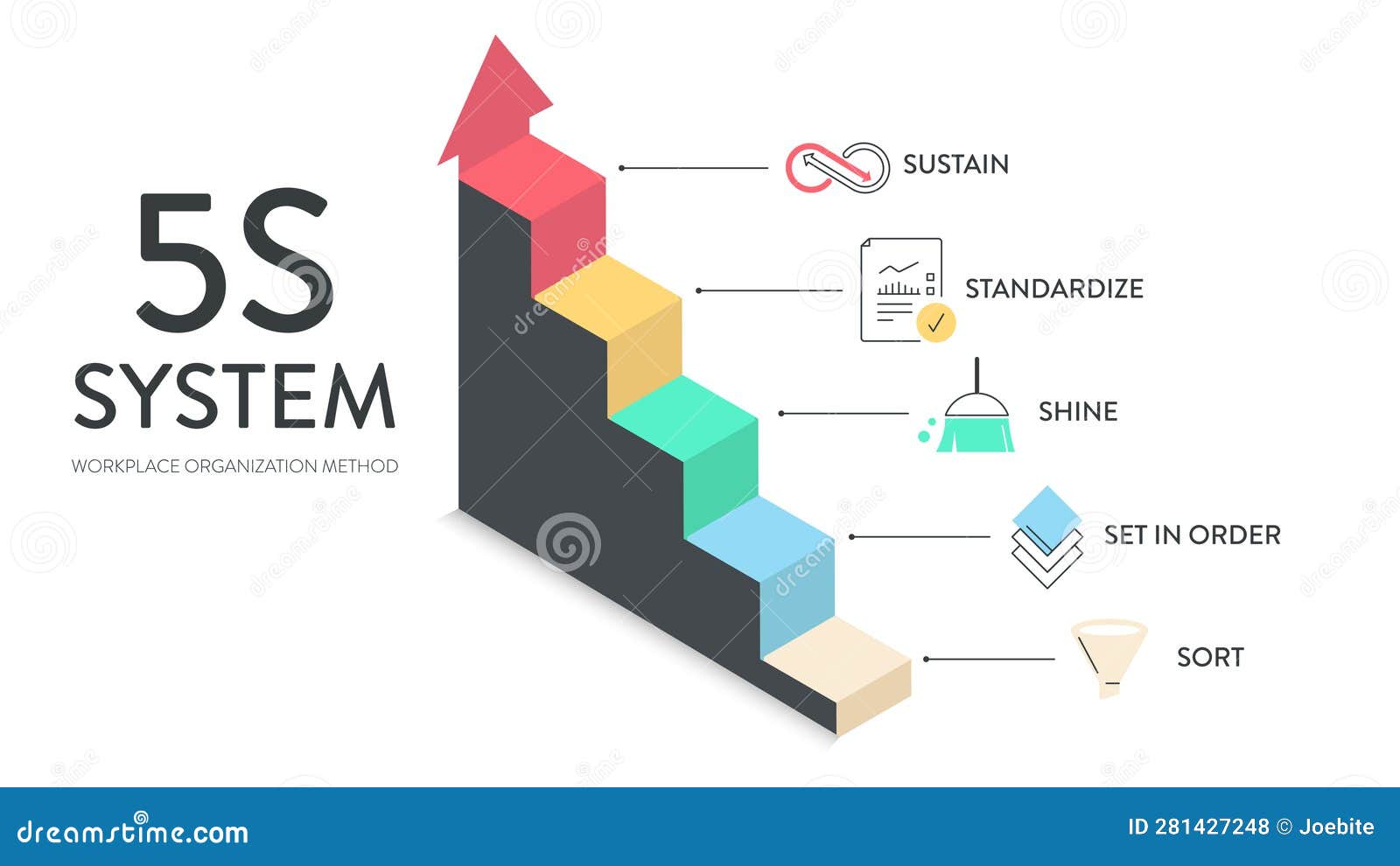

A Vector Banner of the 5S System is Organizing Spaces Industry Performed Effectively, and Safely in Five Steps Sort, Set in Order Illustration de Vecteur - Illustration du industrie, présentation: 281427248

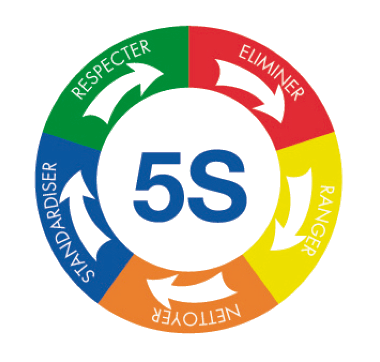

une bannière vectorielle du système 5s organise l'industrie des espaces effectuée efficacement et en toute sécurité en cinq étapes, trier, mettre en ordre, briller, normaliser et maintenir avec un processus lean 9904064

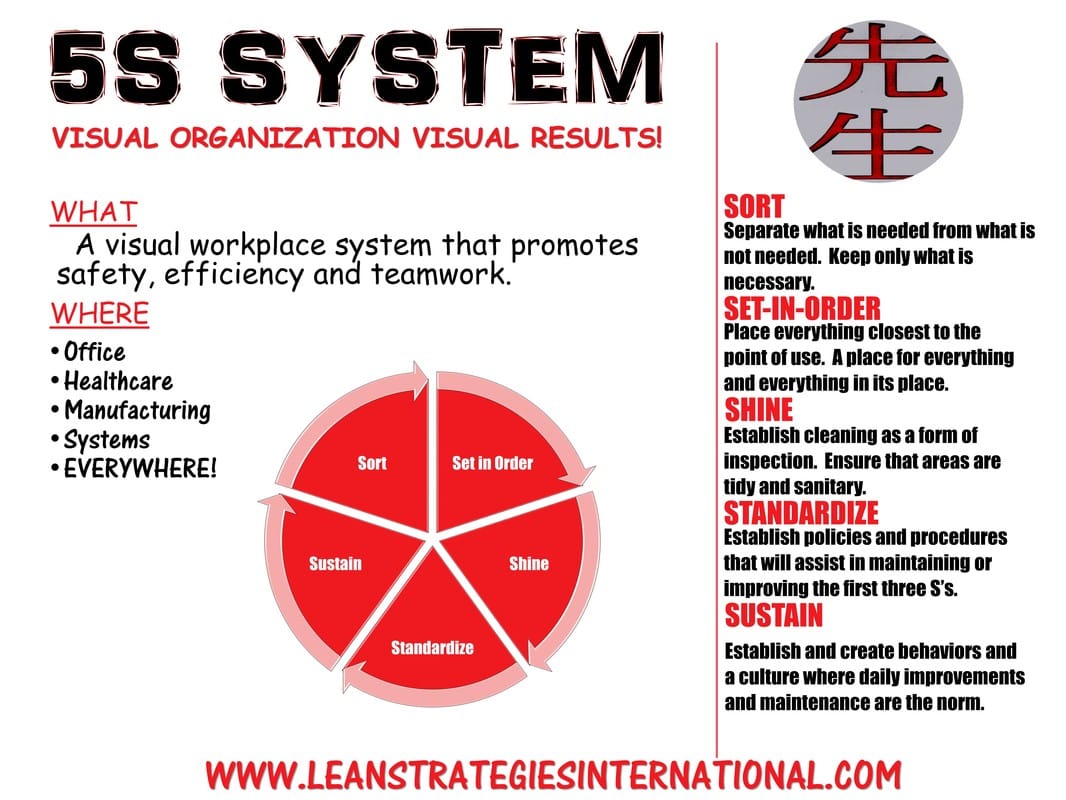

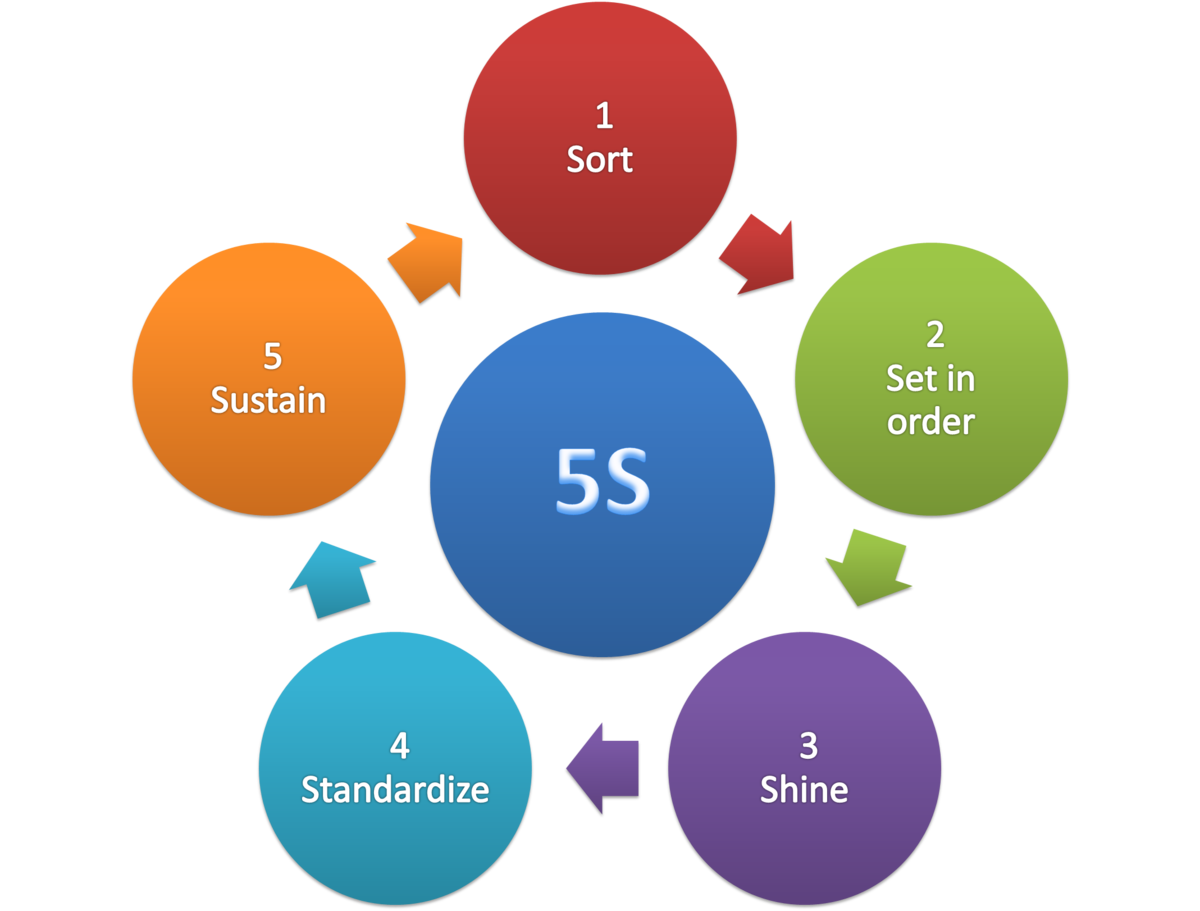

Suvarna Consultants - The 5S System is a #lean #manufacturing tool that improves #workplaceefficiency and eliminates waste. it has 5 pillars. #5Ssystem #LeanManufacturing #VisualManagement #WasteElimination #5S #Leanit #waste | Facebook